When it comes to transporting goods, choosing the right vehicle is crucial to ensure efficiency and safety. Two popular options in the trucking industry are flatbed trucks and box trucks. Each of these vehicles has distinct advantages that cater to different transport needs, making it essential for businesses and individuals to assess their specific requirements before making a decision.

Flatbed trucks are known for their versatile design, featuring an open platform that allows for easy loading and unloading of oversized or irregularly shaped cargo. This makes flatbeds an ideal choice for transporting construction materials, heavy machinery, and other bulky items. Furthermore, the open nature of flatbeds enables quick access during loading, which can be a significant advantage in time-sensitive operations.

On the other hand, box trucks offer a fully enclosed cargo area designed to protect goods from weather conditions and external damage. This makes box trucks particularly well-suited for transporting delicate items, perishables, and products that require additional security. The enclosed design not only safeguards the cargo but also provides a safer environment for the driver and crew during transit.

Deciding between a flatbed and a box truck involves understanding the nature of the goods being transported, delivery timelines, and whether protection from the elements is a priority. By evaluating these factors, you can determine which type of truck is the most suitable for your specific transportation needs.

Flatbed or Box Truck: Which One is Right for You?

Choosing between a flatbed truck and a box truck depends on the specific needs of your business or personal transportation requirements. Each type of truck has its unique advantages tailored to different applications.

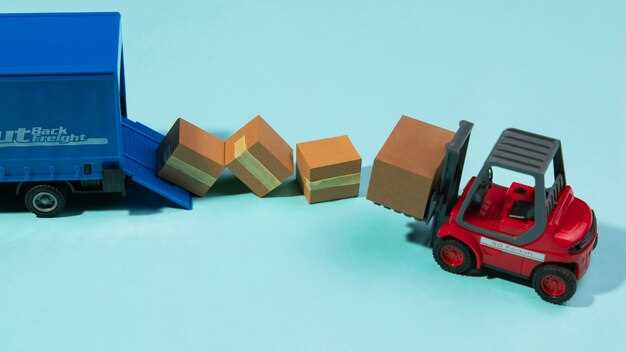

Flatbed trucks feature an open deck design, making them ideal for transporting large, heavy, or oversized items. Their versatility allows for the easy loading and unloading of cargo with cranes or forklifts, which is particularly beneficial in construction or landscaping industries. Additionally, flatbed trucks can accommodate various load types, including machinery, building materials, and lumber, making them a popular choice for businesses that frequently handle non-standard cargo.

On the other hand, box trucks provide an enclosed cargo area, offering enhanced protection against weather elements and security for the transported goods. This makes them suitable for businesses involved in moving furniture, appliances, or delicate items that require extra care during transit. Box trucks also often come equipped with features such as lift gates, which facilitate loading heavy items without needing additional equipment. Their enclosed nature is crucial for companies that need to ensure their cargo remains undamaged throughout the shipping process.

Ultimately, the decision between a flatbed truck and a box truck hinges on the nature of your cargo and operational needs. Consider factors such as load type, required security, and ease of access while evaluating your options. By assessing these variables, you can select the truck that best supports your logistical requirements and enhances your efficiency in transportation.

Cost Comparison: Flatbed vs. Box Truck

When determining the right truck for your transportation needs, understanding the cost implications of flatbeds versus box trucks is crucial. Each type serves a unique purpose and comes with different financial considerations. Below is a breakdown of various cost factors associated with both vehicle types.

Initial Purchase Price

- Flatbed: Typically, flatbed trucks are less expensive to purchase compared to box trucks. They are simpler in design, which often results in lower manufacturing costs.

- Box Truck: Box trucks usually demand a higher initial investment due to their enclosed cargo space and complex construction.

Maintenance Costs

- Flatbed: Maintenance tends to be lower for flatbeds. Their straightforward structure requires less frequent repairs and fewer specialized parts.

- Box Truck: Box trucks may incur higher maintenance expenses due to their enclosed cargo compartments and additional components, such as lift gates and specialized doors.

Operating Costs

- Flatbed: These trucks often have better fuel efficiency because they are lighter and more aerodynamic. This can lead to lower fuel expenses over time.

- Box Truck: While box trucks offer enclosed protection, they may consume more fuel, especially when fully loaded.

Insurance Costs

- Flatbed: Insurance premiums for flatbed trucks can be lower as they are generally considered less risky compared to box trucks, which transport valuable or fragile cargo.

- Box Truck: Insurance costs may be higher, reflecting the increased risk associated with transporting enclosed items.

Resale Value

- Flatbed: Flatbeds tend to retain their value well. Their versatility allows them to serve various applications, appealing to a broader market.

- Box Truck: Resale value may fluctuate depending on market demand for specific cargo types; however, specialized box trucks can sometimes demand a premium if they are equipped with unique features.

Ultimately, the choice between a flatbed and a box truck will depend on your specific hauling requirements, budget, and long-term financial strategy. Consider all the associated costs to make an informed decision that aligns with your operational needs.

Loading and Unloading: Pros and Cons of Each Truck Type

When it comes to transporting goods, selecting the right truck type plays a crucial role in the efficiency of the loading and unloading process. Both flatbed and box trucks have their unique advantages and disadvantages, which can significantly influence your decision.

Flatbed Trucks

Flatbed trucks provide an open platform that facilitates easy access for loading and unloading. This design is particularly advantageous for large or oversized cargo. The main pros of flatbed trucks include:

- Easy Access: The open deck allows for straightforward loading from multiple angles, making it suitable for bulky items.

- Versatility: Ideal for various cargo types, including construction materials, pallets, and machinery.

- Time Efficiency: Quick loading and unloading processes can reduce downtime, increasing overall productivity.

However, flatbed trucks also have certain drawbacks:

- Weather Exposure: Cargo is susceptible to rain, wind, and other weather conditions, necessitating additional protective measures.

- Securing Loads: Properly securing cargo can be more challenging, requiring additional time and equipment.

Box Trucks

Box trucks feature an enclosed cargo area, offering ample protection for goods during transport. Their pros include:

- Weather Protection: Enclosed design shields cargo from environmental factors, reducing the risk of damage.

- Security: Lockable doors provide enhanced security for valuable items while in transit or parked.

- Ease of Organization: The defined space allows for more organized loading, ensuring safe transport of various items.

On the downside, box trucks have some limitations:

- Loading Height: Loading and unloading can be cumbersome, especially for heavy or oversized items due to the limited access points.

- Weight Restrictions: Box trucks often have stricter weight limits, which can restrict the types of cargo that can be transported.

In summary, the choice between flatbed and box trucks for loading and unloading depends on the nature of your cargo and operational needs. Assessing these pros and cons will help in making an informed decision that aligns with your transport requirements.

Best Use Cases: When to Choose a Flatbed Over a Box Truck

Flatbed trucks are often the preferred choice for transporting large, bulky items that do not fit comfortably within the enclosed space of a box truck. When dealing with oversized materials, such as construction equipment, lumber, or industrial machinery, a flatbed truck provides the necessary access and space for loading and unloading without restrictions.

Another scenario where flatbeds excel is in situations requiring quick and efficient loading and unloading. The open design allows forklifts and cranes to easily access the load from all sides, which can significantly reduce the time spent on these operations compared to a box truck.

Flatbeds are also ideal for transporting building materials like steel beams, roofing supplies, and pipes, which often need to be secured but not exposed to weather elements. Utilizing tarps or securing materials with straps ensures protection while maintaining the flatbed’s versatility.

In the agricultural sector, flatbed trucks are commonly used for hauling hay, farm equipment, or livestock. The wide and open design can accommodate diverse cargo types, which a box truck might not be able to handle effectively.

Additionally, if you’re working with freight that requires flexibility in load size and shape, a flatbed truck allows for more diverse cargo configurations. This adaptability makes it a smart choice for businesses engaged in logistics involving variable load sizes.

In summary, flatbed trucks are best suited for transporting large, heavy, or irregularly shaped items, providing flexibility and quick access that box trucks cannot offer. Choosing between the two should depend on the specific requirements of the cargo and the overall operational needs.