In the world of trucking, vehicles are primarily categorized into light-duty and heavy-duty trucks. These classifications play a crucial role in various sectors, from commercial freight transport to personal use. The distinction between the two truck types is not merely about size; it encompasses differences in engine capacity, payload capabilities, and intended applications.

Light-duty trucks are designed for lighter loads and daily operations, making them ideal for personal use, small businesses, and urban environments. Their fuel efficiency and maneuverability are significant advantages, appealing to those who prioritize cost-effectiveness and ease of use in their driving experience.

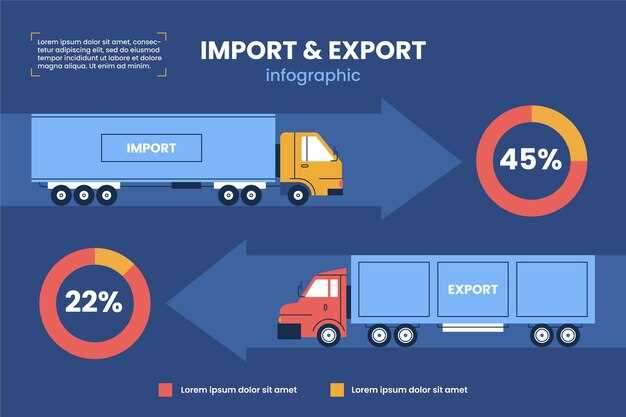

In contrast, heavy-duty trucks are engineered for robustness and durability, tailored for demanding tasks that require higher towing capacities and payload limits. These trucks are the backbone of industries like construction, logistics, and long-haul transportation, where reliability and performance under pressure are essential.

Understanding the differences between light-duty and heavy-duty trucks is vital for anyone involved in the trucking industry or considering a vehicle purchase for specific needs. This article will delve into the features, advantages, and appropriate applications of each truck type, providing clarity in making informed decisions.

Key Differences in Weight and Payload Capacity

The classification of trucks into light-duty and heavy-duty categories fundamentally hinges on their weight and payload capacities. Light-duty trucks typically possess a gross vehicle weight rating (GVWR) under 8,500 pounds, making them suitable for everyday consumer use, such as commuting, light hauling, and recreational activities. In contrast, heavy-duty trucks have a GVWR that exceeds 8,500 pounds, often reaching up to 33,000 pounds or more. This significant weight capacity enables heavy-duty trucks to handle more substantial loads and operate consistently in challenging environments.

Payload capacity is another critical distinction. Light-duty trucks generally offer payload capacities ranging from 1,500 to 3,000 pounds. This limit makes them ideal for moving smaller items, such as furniture or equipment, but unsuitable for industrial-level transport. Heavy-duty trucks, however, can carry payloads exceeding 5,000 pounds, with some models able to accommodate loads exceeding 15,000 pounds. This capacity is essential for businesses in construction, logging, and agriculture, where heavy loads are common.

Additionally, the structural design of heavy-duty vehicles contributes to their increased weight and payload capabilities. These trucks are equipped with robust frames, reinforced suspensions, and powerful engines to handle strenuous conditions. Light-duty trucks, while still versatile, utilize lighter materials and may not incorporate the same level of structural reinforcements, which limits their overall payload potential.

Ultimately, understanding the key differences in weight and payload capacity is crucial for selecting the right truck for specific needs, ensuring that the vehicle can adequately handle intended tasks without compromising performance or safety.

Choosing the Right Truck for Specific Applications

When selecting a truck for specific applications, understanding the distinctions between light-duty and heavy-duty trucks is crucial. Each category serves distinct purposes and offers unique advantages. Light-duty trucks, typically defined by their lower payload capacities and smaller engines, are ideal for personal use, commuting, and light commercial tasks. They excel in maneuverability and fuel efficiency, making them suitable for urban environments and small businesses.

In contrast, heavy-duty trucks are designed for more rigorous demands, including transporting larger loads and operating in tougher conditions. Their robust construction and powerful engines provide the necessary strength for construction sites, long-haul transportation, and heavy towing applications. Businesses involved in logistics, construction, or agriculture often rely on heavy-duty trucks to ensure productivity and efficiency.

For businesses or individuals involved in tasks such as landscaping, home improvement, or light freight transport, light-duty trucks offer the perfect balance between capability and comfort. They can easily navigate city streets and provide sufficient cargo space without incurring the higher costs and complexity associated with heavy-duty models.

On the other hand, if your work involves hauling heavy equipment or materials over long distances, investing in a heavy-duty truck is essential. These vehicles not only provide greater towing capacities but also come equipped with advanced safety features and durability to withstand harsh environments.

Ultimately, the choice between a light-duty and heavy-duty truck hinges on the specific needs of your application. Assessing factors such as payload requirements, frequency of use, and operational environment will guide you in selecting the right truck to optimize performance and meet your operational goals.

Maintenance Considerations for Light-Duty vs Heavy-Duty Trucks

When it comes to maintenance, light-duty and heavy-duty trucks require different approaches due to their fundamental differences in structure, use, and operational demands. Understanding these distinctions is vital for truck owners and operators to ensure vehicle longevity and efficiency.

Light-duty trucks typically serve personal or small business purposes, often being used for short-distance travels or light hauling tasks. Their maintenance schedule is less intensive compared to their heavy-duty counterparts. Generally, routine maintenance for light-duty trucks involves regular oil changes, tire rotations, and inspections of brake systems. The intervals for these tasks may be spaced out further due to the less demanding nature of light-duty operations.

On the other hand, maintaining heavy-duty trucks is a much more comprehensive endeavor. These trucks are designed to handle significant loads and long-distance travel, which places a greater strain on their components. Maintenance for heavy-duty trucks often includes more frequent inspections of the drivetrain, suspension, and braking systems, as well as regular checks on the engine and transmission to ensure optimal performance under heavy loads.

Another critical aspect of maintenance differences is parts replacement. Light-duty trucks may require less frequent part replacements, while heavy-duty models might need more robust components that can withstand higher usage. For example, heavy-duty tires are designed specifically for durability and may have to be replaced more often due to regular exposure to harsh conditions and heavy cargo.

Additionally, fluid management is crucial for both types of trucks but varies significantly. While light-duty trucks often utilize standard motor oils and transmission fluids, heavy-duty trucks may require specialized lubricants that can endure high-temperature conditions and extended operational periods. Regularly checking and replacing these fluids is vital in preventing mechanical failure.

Finally, professional servicing plays a pivotal role in maintaining both light-duty and heavy-duty trucks. While light-duty vehicles may be serviced by general auto repair shops, heavy-duty trucks often benefit from specialized mechanics who understand the complex systems and regulations governing commercial vehicles. Therefore, investing in qualified technicians can lead to more efficient maintenance practices and better overall vehicle performance.